Roller Conveyors

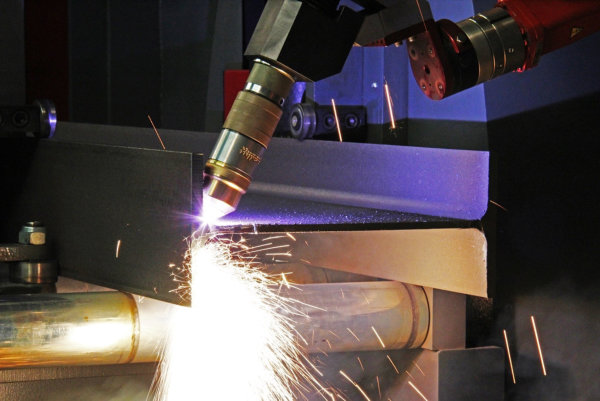

With us at Gulf States Saw & Machine Co., there is an assurance that our Robotic Coping and Profiling is second to none in the industry with its high definition plasma technology system that is capable of cutting through a wide range of metal profiles for not only structural steel but other metal pieces.

Receive exclusive offers and information about the latest products and technology. We'll add your email to the mailing list!